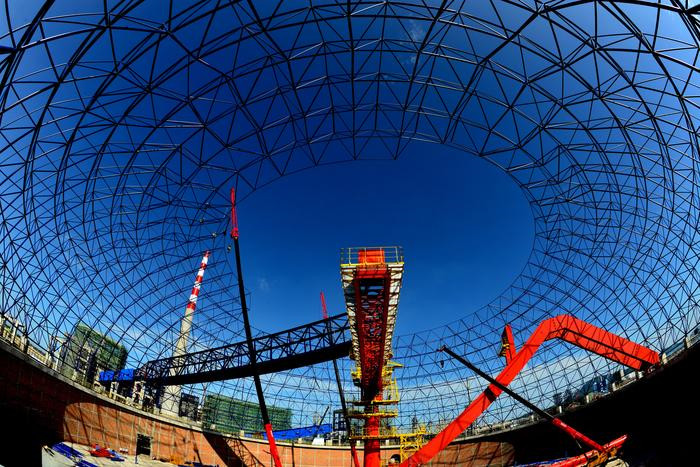

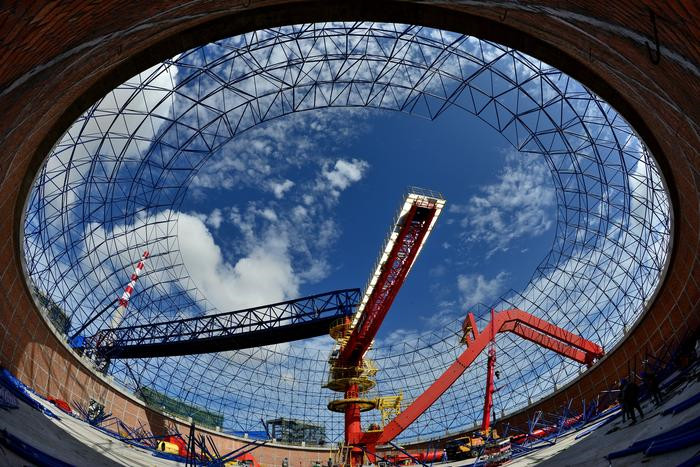

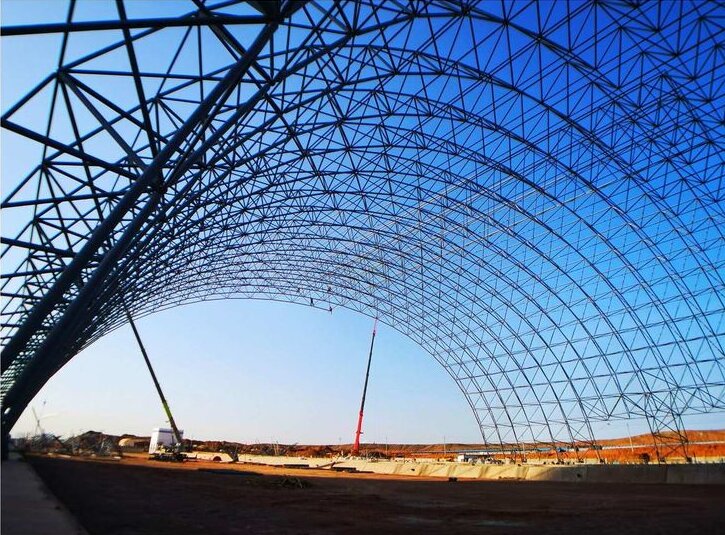

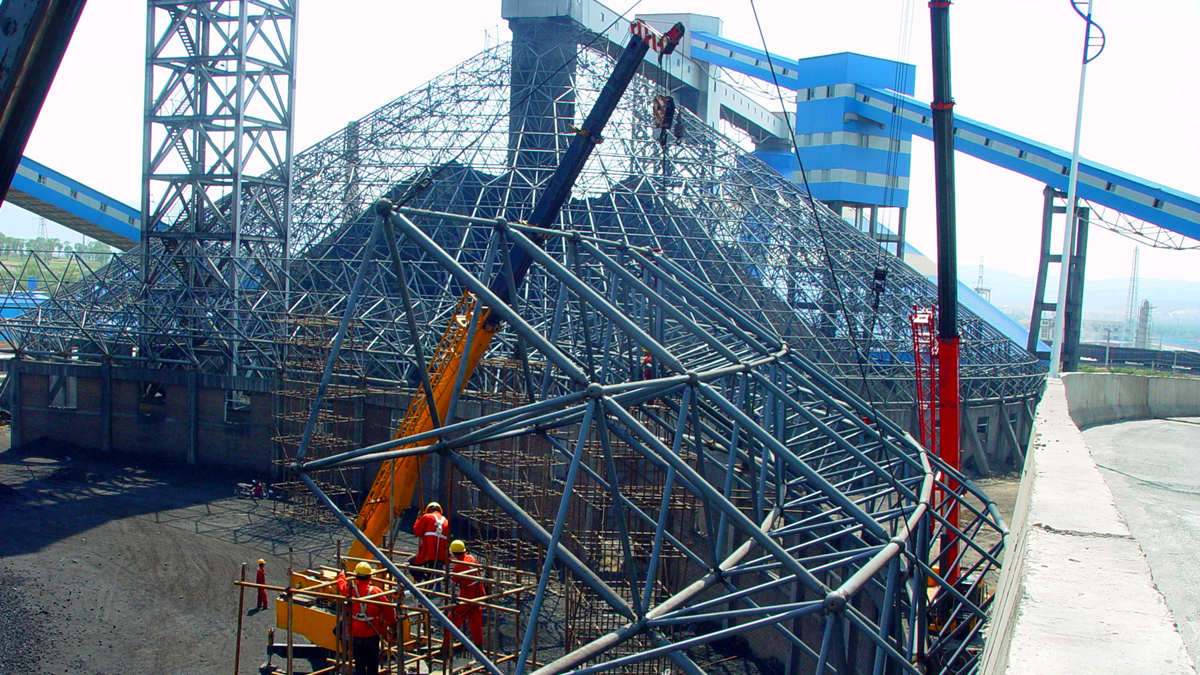

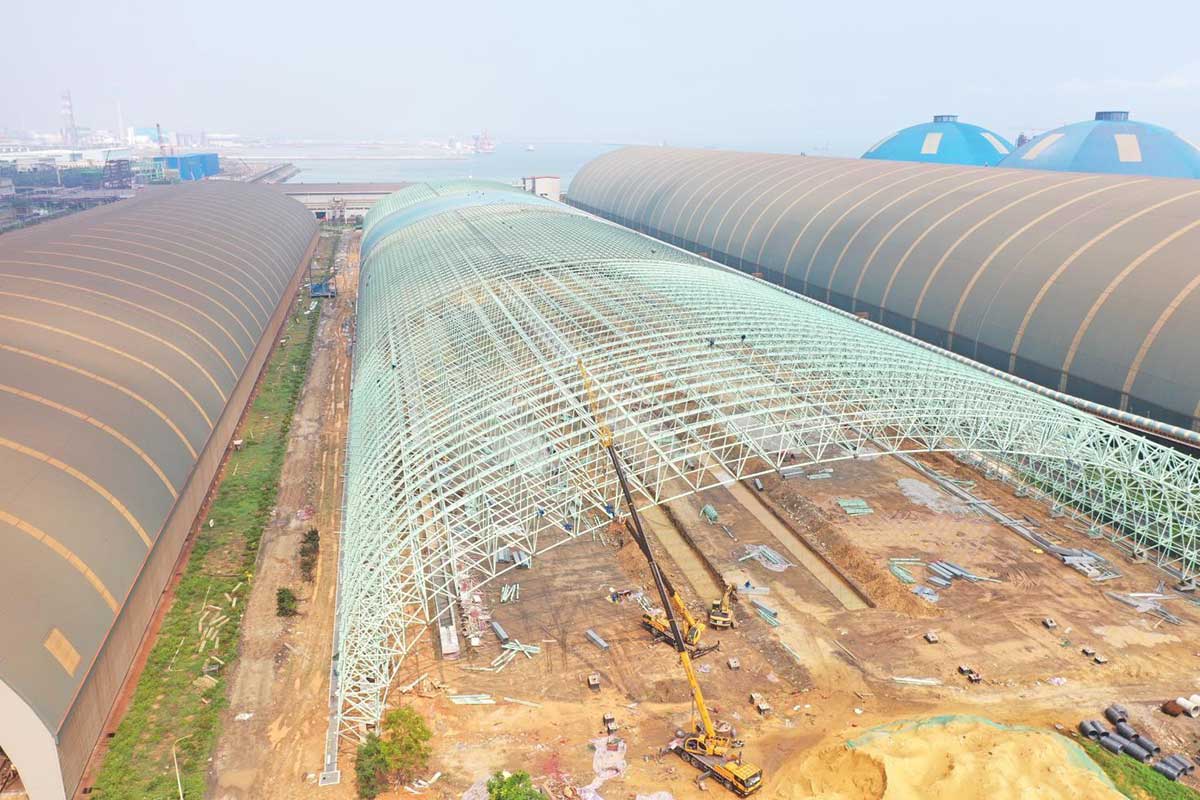

The storage and transportation facilities of the steam and electricity co-generation unit of Gulei petrochemical integration project have two coal storages with a diameter of 100 meters and coal transport systems. In order to ensure coal storage on schedule and open up the transportation process from coal bunker to steam and power co-production main device, the company organized construction forces to fully launch the steel dome space frame connection installation of its 1# coal storage, and the installation of coal transport system in the plant was also intensified.

The co-generation unit of Gulei Petrochemical Integration project is the “power source” that provides steam, and electricity for the whole process unit of Gulei petrochemical integration project, the coal bunker and transportation facilities plays the role of providing fuel coal for the boiler island storage of the co-generation unit.

The steel space frame of 1# coal storage starts from 23.8 meters in elevation and finally closes at 52 meters in elevation. Since late June, in response to the daily on-site temperature reaching more than 40 degrees Celsius since the beginning of summer, the company has organized a professional installation team of the space frame, taking the wrong time to avoid the hottest time at noon, and carrying out the installation and connection of the coal storage space frame composed of 1574pcs ball heads and about 13,900pcs bars in the air.

.jpg)

.jpg)

.jpg)