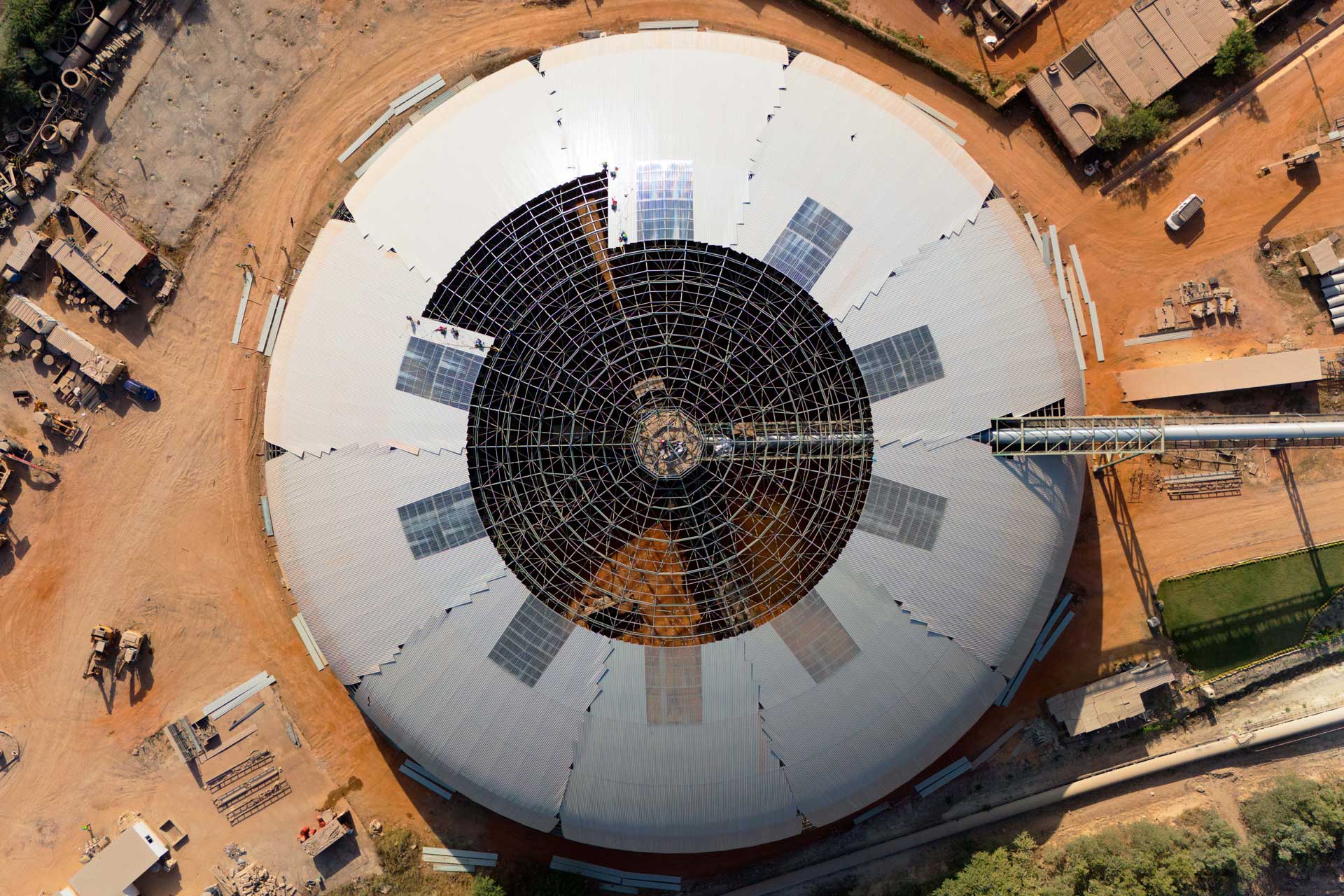

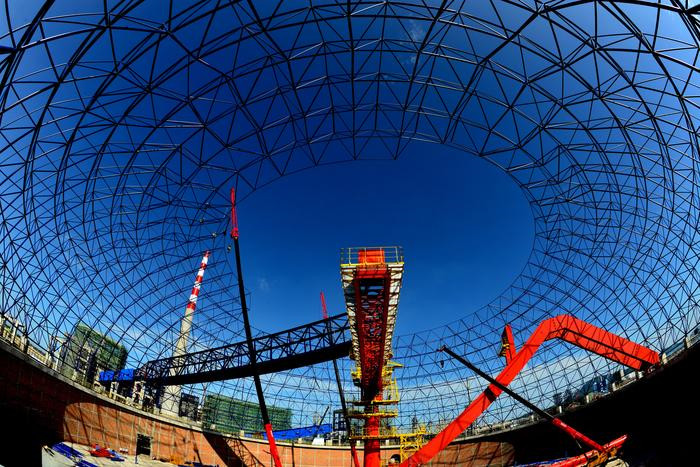

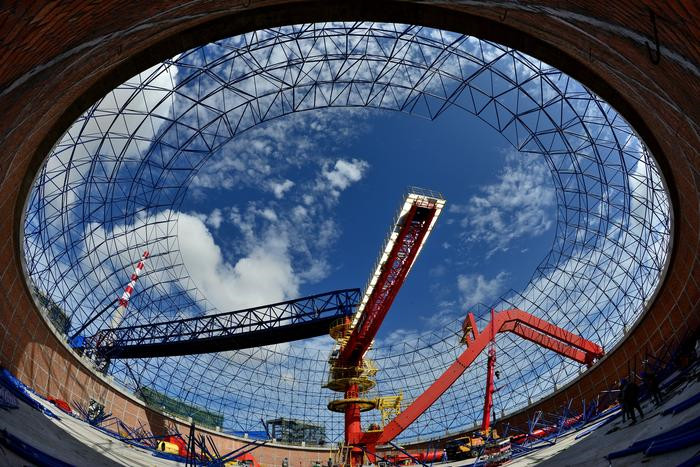

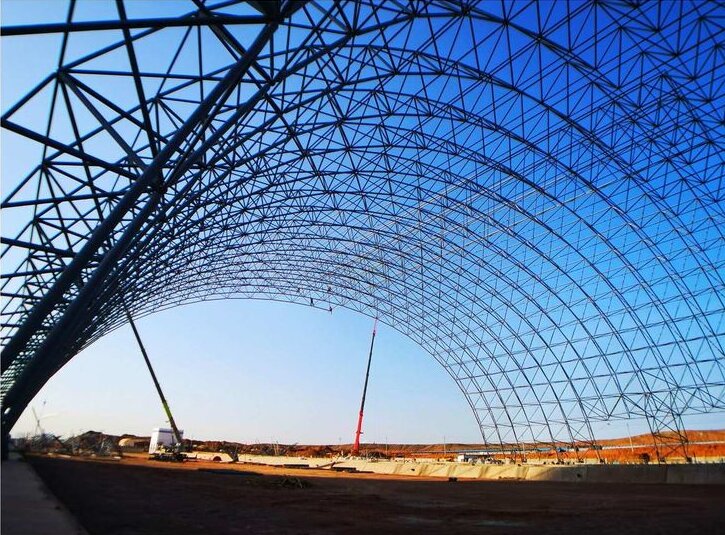

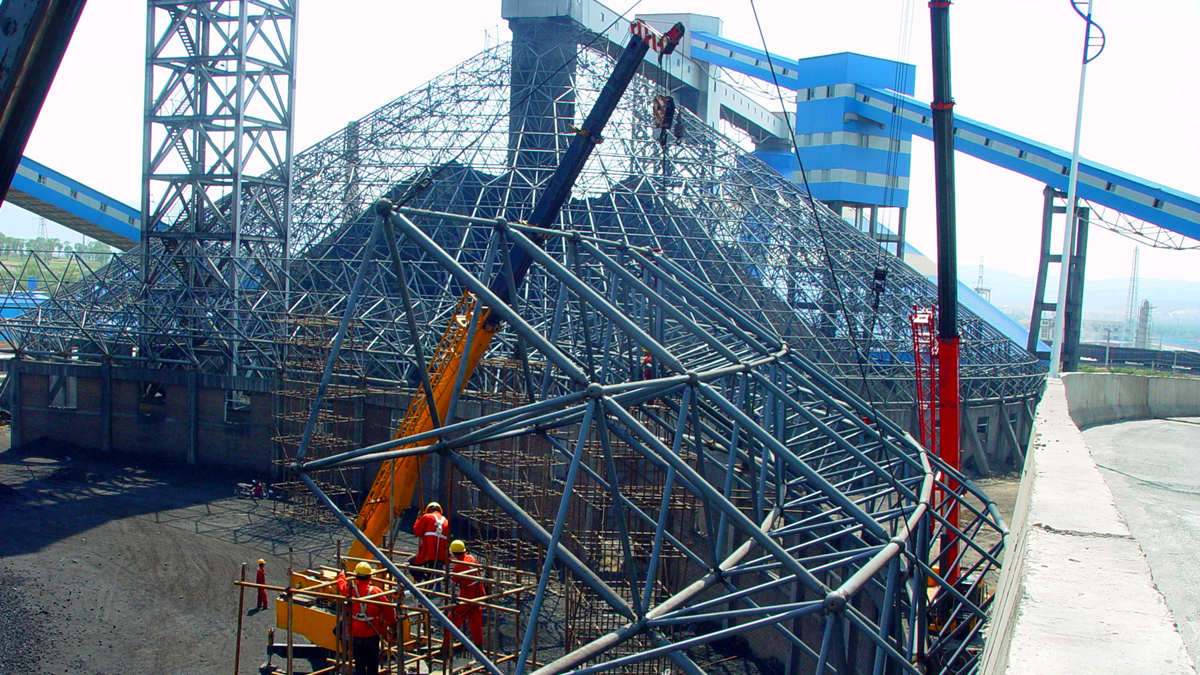

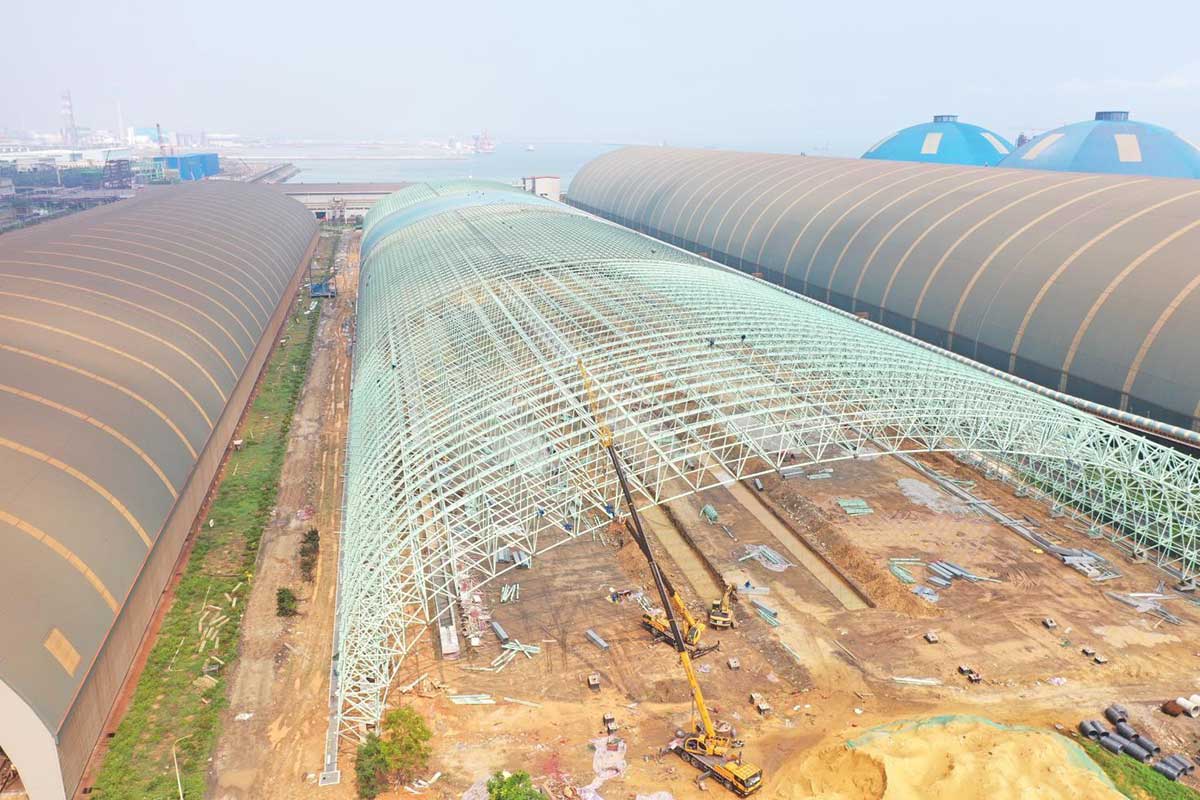

Our company delivered enclosed dome space frame premix storage building for Cement Plant. The structure combines a Φ107.02m spherical grid with 33.05m peak height, demonstrating cutting-edge steel construction capabilities.

- Advanced Spatial Structural System

- this premix storage building adopts fully enclosed bolt-ball joint double-layer space frame structure

- Achieves superior mechanical performance through orthogonal square pyramid grid layout, resisting strong earthquakes and wind loads 5

- Enables 95% factory prefabrication rate, reducing onsite assembly time by 40% versus conventional methods

- Smart Construction Technologies

- BIM-driven 3D modeling ensures ±2mm component precision 1

- Robotic welding systems maintain 100% non-destructive testing compliance

- Satellite positioning coordinates 107m-span component alignment

- Eco-Friendly Enclosure System

Roaming System Components:

✓ C-shaped purlins: Q345B cold-formed steel, 2.5mm wall thickness @1.2m spacing

✓ 0.75mm color-coated panels: Al-Zn coating + PVDF finish, 25-year service life

✓ 1.5mm FRP daylighting panels: 75% light transmission + 99% UV filtration

.jpg)

.jpg)

.jpg)